The Benefits of SKU-Level Modeling and Forecasting

February 19, 2021 | by: David Phillips

Companies that manage large numbers of Stock Keeping Units, more commonly known as SKUs, often run into the issue of being able to plan and forecast at scale. Whether they are a manufacturer, wholesaler or retailer, organizations face significant challenges when modeling products that number in double digits, hundreds or even thousands. Yet, modeling at the SKU level creates real advantages as it provides a solid foundation for more accurate financial and operational planning and execution.

SKU Gross Margin Analysis

Modeling at the SKU level reveals insights that are masked by modeling the average of product families. For a simple example, Product A has a gross margin of 75% and Product B has a gross margin of -25%. Product family A/B has a gross margin of 50%, provided they are equally weighted. By understanding this, you may consider discontinuing Product B to increase overall profit margin. This type of modeling insight is valuable when planning and running scenarios for new products as well. For this reason, it makes financial sense to model at the most granular level.

SKU Cost Modeling and Analysis

SKU modeling is often complex and entails a number of different elements. For modeling of costs, it could comprise a bill of materials (BOM) that includes numerous raw materials or components with different cost structures. Material costs vary over time and any changes in cost can either positively or negative impact profitability. Organizations will try to model certain BOM mixes to achieve the lowest per unit cost. Trying to manage this effort in spreadsheets can be overwhelming.

Manufacturing Cost Per Unit

Manufacturing cost per unit is a typical key performance indicator (KPI) that includes the cost of direct labor plus overheads divided by units. Combined with BOM modeling, this KPI can also include material costs, which are often not part of this calculation due to external material cost fluctuations. This is a valuable measure of manufacturing efficiency, as it allows companies to gauge the impacts of any process improvements they implement.

Product Pricing

With detailed knowledge around product costs, organizations can adjust their pricing to maintain a specific margin. For products whose pricing can’t deviate from the market or commodity price, they may seek to optimize the manufacturing process to gain efficiencies that lower the cost. Alternatively, they may seek a lower cost supplier. Having real-time access to current and projected costs enables manufacturers to adjust prices accordingly, thus ensuring margin and profitability. This is particularly impactful when applied across the full spectrum of SKUs.

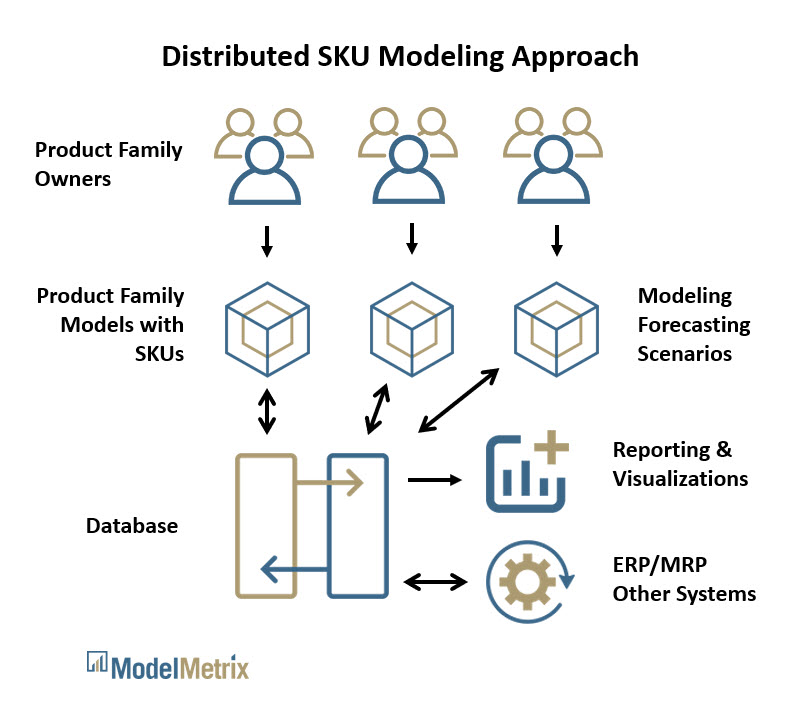

The Challenge and Solution to Large-Scale SKU Modeling and Forecast

Many organizations would like to forecast at the SKU level. However, they often then reach the point where the time and effort to adjust the forecast becomes unmanageable. By distributing the modeling effort across product family owners and other stakeholders, the work can be made more manageable. Product family owners have access to the multi-dimensional models specific to their SKUs. Once they have completed their updates, the data is pushed to a centralized database (or data warehouse) where the data is aggregated with other SKUs and product families.

A Better Approach to SKU Modeling

At Model Metrix, we build integrated SKU models that address the complex aspects of product planning – a process that breaks down with spreadsheets or falls outside of MRP/ERP and legacy planning tools. We leverage Quantrix Modeler, the leading multi-dimensional modeling platform, to quickly and cost-effectively create models for clients. Our solutions fit within a client’s broader solution and IT ecosystem. Modeled data and scenarios can be pushed into a data warehouse for consumption by G/L and planning systems. Data can be readily accessed by BI tools for reporting to broader group of stakeholders. By modeling at the SKU level, organizations are better positioned to ensure financial and operational performance.

We would love to hear about your SKU modeling challenges. Contact us for a free discovery call.